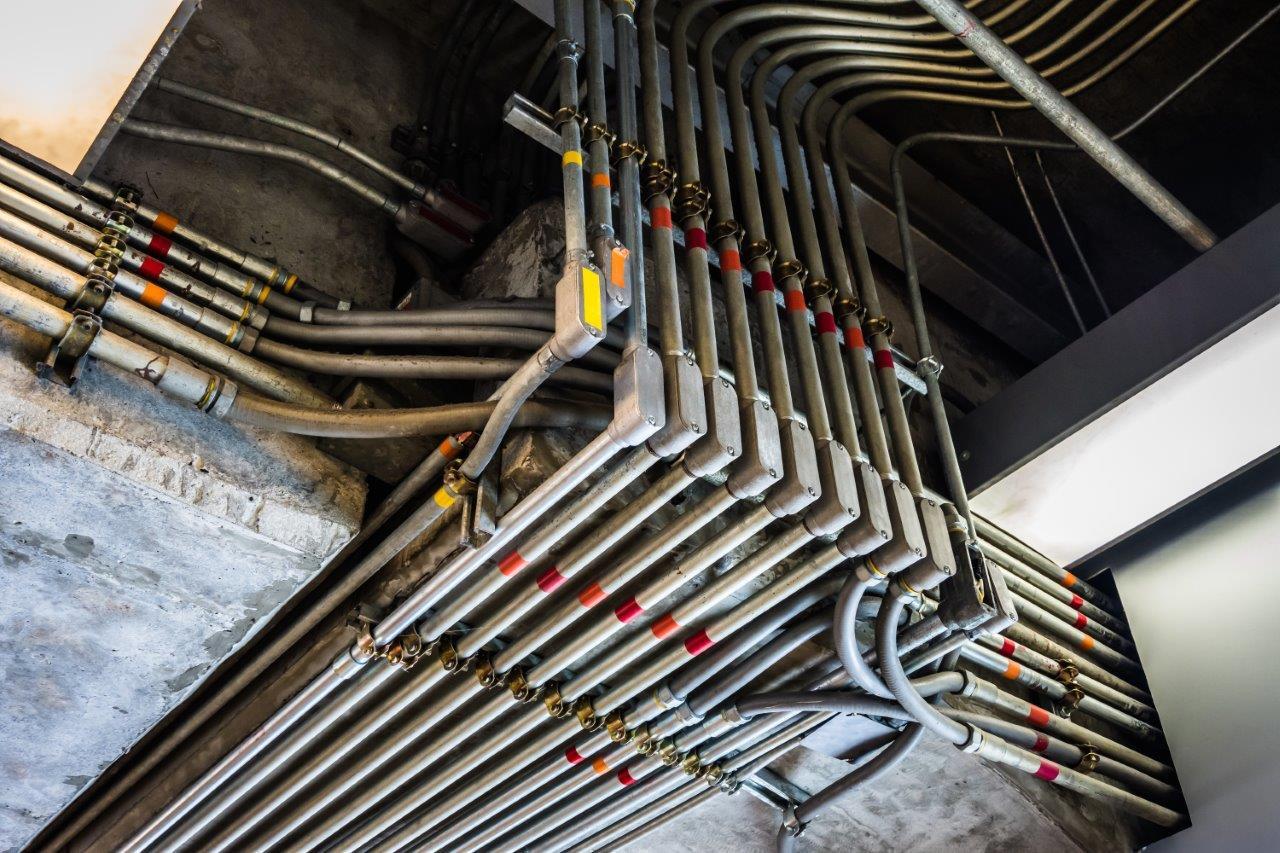

Electrical conduit is tubing made of various materials used in electrical wiring. Its purpose is to shield electric conductors inside and route wiring through different areas in both residential and commercial buildings. Based on the material used and whether it is rigid or flexible, there are several types of electrical conduit, along with various accessories and fittings that allow for clean-cut wiring solutions and the ability to upgrade wiring when adding additional conductors.

Types of Electrical Conduit

- Electrical Metallic Tubing (EMT), also called a thin-wall conduit is a thin, lightweight conduit that is easily formed or bent. It is mostly in the form of galvanised steel, but there are also aluminium variants. It is sturdy, resistant to rust, moisture and heat, and ideal for outdoor uses. For this purpose, it is often seen in commercial and industrial premises, but also in residential buildings where additional protection is needed.

- Rigid Metallic Conduit (RMC) comes in the form of thick steel pipes and is used exclusively for heavy-duty industrial wiring where large amounts of current and high voltages are involved. It is the heaviest conduit type, but with the best protective qualities. It is rigid in that is formed only by specialised tools, but also offers structural support for connecting items, like electrical panels. Since its specific use, it also is one of the more expensive options.

- Intermediate Metallic Conduit (IMC) has the same diameter as RMC but contains less steel, so is thinner. It is used in similar cases as RMC, for wiring in industrial buildings, and has similar resistance to corrosion, heat and moisture. It is a cheaper and newer solution to traditional rigid metal conduits.

- Flexible Metal Conduit (FMC) is made of interlocked aluminium or steel coils, making it very easy to bend. It’s mainly used indoors, where other conduits would be hard to form and pull. Plastic coated FMC is watertight and known as Liquid-tight Flexible Metal (LFMC), good for use in outdoor situations where moisture or water can be an issue, like wiring air conditioners.

- Electrical Non-Metallic Tubing (ENT) or corrugated conduit is a flexible thin-wall substitute for EMT and has good fire and moisture resistance. It is often used in indoor residential wiring.

- PVC Conduit is the lightest but offers resistance to corrosion and moisture. However, specific types are not intended for areas with direct sunlight, as this degrades the material over time. Though rigid, it can be easily bent and formed. PVC Conduit is the cheapest type on the market and is widely used. It comes in different lengths and widths, making it useful in many wiring applications. Grey PVC conduit is used in installing cables above ground, whereas heavy-duty orange-coloured conduit is for underground cable routing.

Different types of conduits are suitable for different applications. Industrial wiring requires additional protection due to higher voltages and surroundings that generate heat and moisture. Here, EMT or RMC are preferred, but IMC can serve as a substitute. Residential uses often require flexible conduits like FMC or ENT, but rigid PVC conduit is also used in some cases.

Conduit Accessories

ENT and PVC conduit is easily cut, bent and formed to fit the required surface along which wires will run. Pieces of adjoining conduit are connected by a system of couplings, bends and elbows in the appropriate diameter and the same material as the conduit. ENT and PVC couplings and elbows are therefore PVC, while metal conduits will have metal couplings and elbows.

Lock rings are used at either end of couplings for a secure connection. Sweep bends are used to attach pieces of conduit in a long radius sweep, allowing for a free-flowing connection. T- junctions and inspection boxes connect conduit at a right angle. All wiring terminates in a junction box of the same material as the conduit. Metal conduit types will have metal junction boxes, and plastic conduit types will have plastic junction boxes.

Saddles

Electrical saddles are clamps or straps available in a variety of materials, used to secure conduits to different surfaces. They’re spaced at even lengths along the surface to provide adequate support to the conduit. Electrical saddles are sold in various widths to accommodate the width of the conduit they’re supporting. There are two basic types – full and half saddles. Full saddles have two fastening holes, whereas half saddles have one. Different materials are also used. Zinc-plated steel saddles are used in securing both metal and plastic conduit types. PVC saddles are used mainly for non-metallic conduits, often in residential applications. For surfaces that need regular cleaning there are also distanced or ‘hospital’ saddles which provide enough space between the conduit and the supporting surface for things like cleaning cloths.

Buying Electrical Conduit and Accessories

If you’re a professional electrician and know what you need for your wiring project, a good idea is to compare conduit and accessory prices online. Steel conduit of the EMT and RMC types and accompanying metal fittings are found through industrial wholesalers. They don’t come cheap though. Corrugated and PVC conduit and accessories can be found in most hardware chains and electrical stores. Conduit of this type is sold in pre-cut lengths and in widths to suit your needs. You’ll find a range of couplings, bends, saddles, electrical boxes, junctions, terminating ends and all necessary additions at affordable prices.